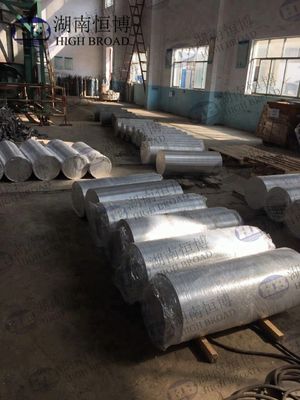

ISO9001:2008 Certified Direct Chill Cast Magnesium Billet and Rod with Custom Size Options

Dettagli:

| Luogo di origine: | Hunan, Cina |

| Marca: | high broad |

| Numero di modello: | az31 |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 100 |

|---|---|

| Prezzo: | $50 |

|

Informazioni dettagliate |

|||

| Composizione chimica: | Magnesio | Materiale: | lega di magnesio |

|---|---|---|---|

| Forma: | Tondo, barra, asta | Densità: | 1,8 g/cm3 |

| Diametro della billetta: | Da 90 mm a 600 mm | Lunghezza della billetta: | 4500mm |

| spessore della lastra: | 340 mm | Larghezza lastra: | 960 mm |

| Lunghezza lastra: | 2000mm | Tipi di lega: | AZ31B, AZ61A, AZ80A, ZK61M |

| Standard di ispezione: | AMS-STD-2154 Classe A | Trattamento superficiale: | Prevenzione temporanea della corrosione |

| Spessore massimo: | 340 mm | Larghezza massima: | 960 mm |

| Lunghezza massima: | 2000mm | ||

| Evidenziare: | ISO9001:2008 Certified Magnesium Billet,Direct Chill Cast Magnesium Rod,Custom Size Magnesium Alloy Billet |

||

Descrizione di prodotto

Direct chill cast billet serves as the primary material for manufacturing various magnesium products including sheet, plate, forgings, and extrusions. These billets are also suitable for machining prototypes, eliminating the need for expensive tooling, and can be used for production when finished item dimensions exceed standard casting or extrusion capabilities.

- Diameter range: 90mm to 600mm

- Maximum length: 4500mm

- Available alloys: AZ31B, AZ61A, AZ80A, ZK61M

- Inspection standard: AMS-STD-2154 Class A

- Optional temporary corrosion preventative surface treatments

Our direct chill continuous cast machining slabs enable production of parts larger than conventional methods allow. These rectangular slabs feature two opposing machined faces and edges (when required), cut to ordered specifications.

| Dimension | Maximum Size |

|---|---|

| Thickness (after machining) | 340mm |

| Width (after machining) | 960mm |

| Length (after sawing) | 2000mm |

Special alloy and size combinations available upon request.

Magnesium alloys (density: 1.74 g/cm³) offer significant weight reduction benefits for aerospace applications. Every 1 pound of weight reduction translates to substantial cost savings:

- Commercial aircraft: $300 savings

- Fighter jets: $3,000 savings

- Spacecraft: $30,000 savings

Beyond cost reduction, weight savings improve flight performance by reducing inertia while maintaining superior strength and stiffness compared to engineering plastics.